Search

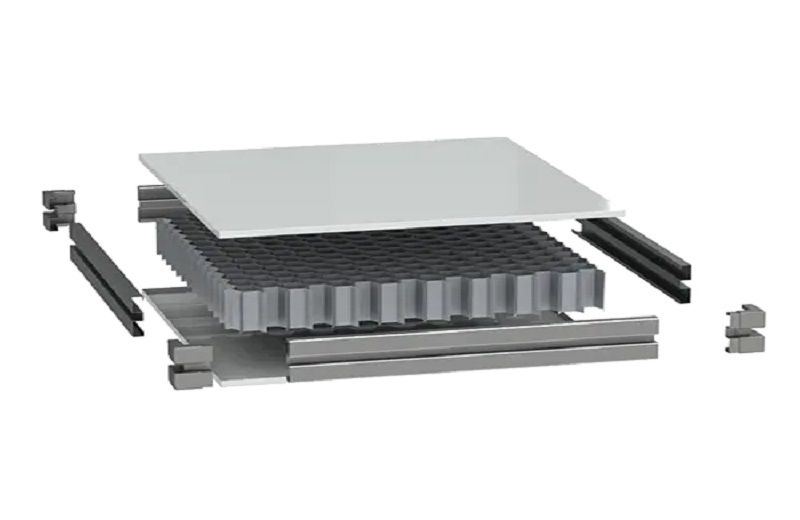

Selecting the right insulation material is critical for achieving energy efficiency, cost savings, and long-term sustainability. While traditional materials like fiberglass, mineral wool, and polystyrene have been widely used, PUF (Polyurethane Foam) panels are increasingly preferred for their superior insulation, durability, and efficiency. This analysis compares PUF panels with conventional insulation solutions across key performance metrics.

PUF Panels: Extremely low thermal conductivity (~0.022 W/mK), ensuring excellent insulation with thinner layers.

Traditional Materials:

Fiberglass (~0.04 W/mK): Moderate, performance decreases with moisture.

Mineral Wool (~0.035 W/mK): Better than fiberglass, fire-resistant but heavy.

EPS/XPS (~0.032–0.038 W/mK): Decent but less effective than PUF.

Spray Foam: Similar to PUF but more costly to apply.

✅ Winner: PUF Panels

PUF Panels: Reduce energy use for heating/cooling by up to 40–50%, cutting long-term costs.

Traditional Materials: Require thicker layers, may degrade over time, increasing energy bills.

✅ Winner: PUF Panels

PUF Panels: Prefabricated modules, quick installation, add structural strength.

Traditional Materials: Labor-intensive; spray foam requires professional application.

✅ Winner: PUF Panels

PUF Panels: Lifespan 25–30+ years, resistant to moisture, mold, and pests.

Traditional Materials: Performance drops in humid conditions; polystyrene vulnerable to UV.

✅ Winner: PUF Panels

PUF Panels: Fire-rated variants available; untreated foam can be flammable.

Traditional Materials: Mineral wool is naturally fire-resistant; fiberglass non-combustible; polystyrene highly flammable.

✅ Winner: Depends on application

PUF Panels: Lower carbon footprint via energy savings; eco-friendly blowing agents emerging.

Traditional Materials: Some recycled content (fiberglass/mineral wool), but high production energy; polystyrene non-biodegradable.

✅ Winner: PUF Panels

PUF Panels: Higher upfront cost, but significant long-term savings.

Traditional Materials: Cheaper initially, less efficient, may require replacement.

✅ Winner: PUF Panels

While traditional insulation materials remain in use, insulation PUF panels clearly outperform them in thermal performance, energy savings, durability, and lifecycle cost-effectiveness. For businesses and developers seeking a modern, sustainable, and high-performance solution, PUF panels are the superior choice for residential, commercial, and industrial applications.

Investing in PUF panels means lower costs, higher efficiency, and a greener future.

Product Hub of HEADSTREAM:

English

English  Español

Español  العربية

العربية