Search

In cleanroom construction, selecting the right sandwich panel clean room is essential to ensure airtightness, cleanliness levels, and overall structural stability. As a premium type of cleanroom panel, manual clean room panels are widely used for wall and ceiling systems in clean environments across the pharmaceutical, biotechnology, electronics, and food industries. They stand out for their superior structural strength, customizability, and excellent on-site adaptability.

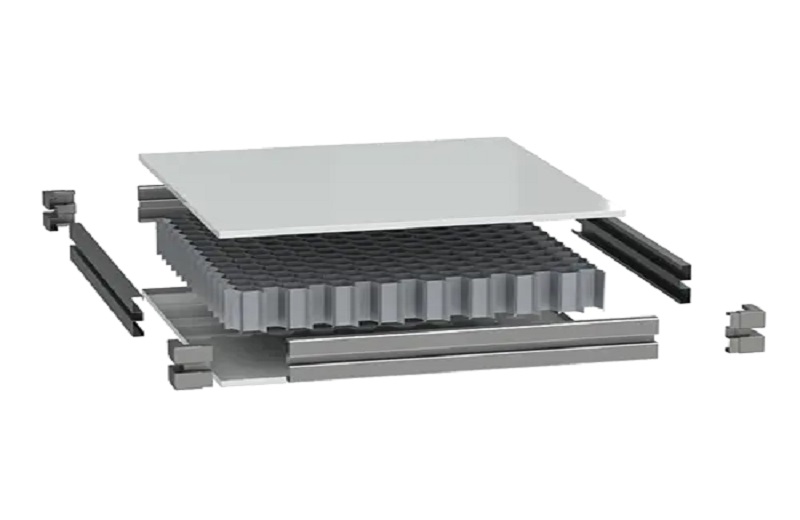

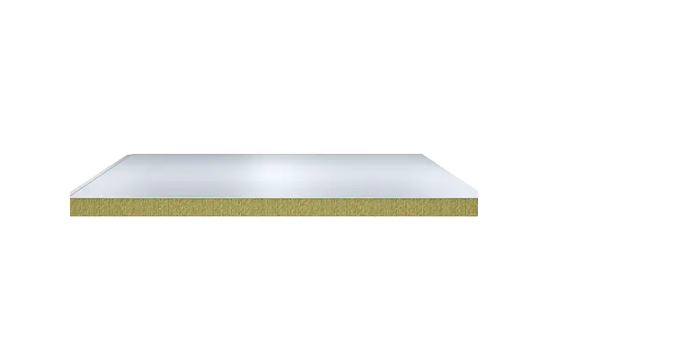

Manual clean room panels adopt a box-type sandwich structure with an internal frame system, giving them outstanding flatness and strength. All four sides are embedded with arched galvanized steel keels, significantly enhancing the panel's load-bearing capacity and extending its service life.

For wall applications, panels are joined using center-aligned aluminum profiles, while ceiling panels utilize concealed suspension beams, achieving seamless connections and clean aesthetics. Panels are interlocked via aluminum connectors, ensuring tight fits and easy installation, thereby improving construction efficiency.

As a high-performance clean room sandwich panel solution, manual panels offer multiple dimensional and core material configurations. Below is an overview of key specifications and options:

| Specification | Details |

|---|---|

| Panel Type | Box sandwich panel clean room |

| Standard Width | 980mm / 1180mm (Custom widths from 75mm to 1180mm available) |

| Typical Thickness | 50mm / 75mm / 100mm |

| Recommended Length | ≤ 7m for walls; ≤ 3m for ceilings (reinforcement recommended if longer) |

| Core Material Options | Dual magnesium oxide + rock wool, single magnesium oxide + rock wool, etc. |

| Performance Features | Fire resistance, sound insulation, thermal insulation |

This high level of adaptability ensures that manual clean room panels can be precisely tailored to project-specific needs, maintaining performance while controlling costs.

On construction sites, manual clean room panels support plug-and-play installation. Features such as removable outer-arc connectors and unified integration between ceiling and wall panels help standardize and simplify the entire installation process.

Both conventional flat panels and box-structured panels are fully compatible within the same system, offering enhanced installation flexibility. This allows construction teams to respond more efficiently to on-site layout changes or design adjustments.

As cleanroom design and construction continue to evolve toward higher standards, HEADSTREAM's manual clean room panels have earned widespread industry recognition for their outstanding structure and customizable configurations. By optimizing key specifications, installation techniques, and application scenarios, HEADSTREAM remains committed to delivering reliable, efficient, and sustainable sandwich panel clean room solutions for diverse industry users.

English

English  Español

Español  العربية

العربية