Search

In today’s fast-growing fields of pharmaceuticals, electronics, food processing, and biotechnology, the demand for dust-free, sterile, and controlled environments is higher than ever. To meet these requirements, clean room sandwich panel has become the preferred building material for constructing advanced clean environments.

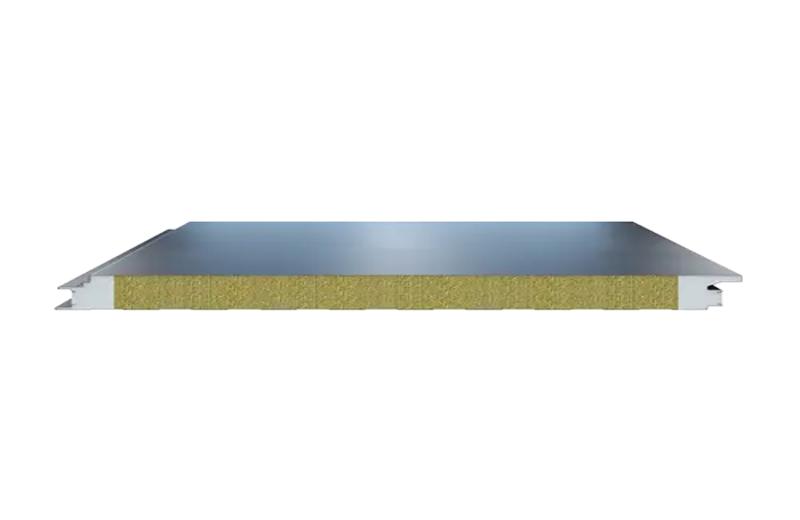

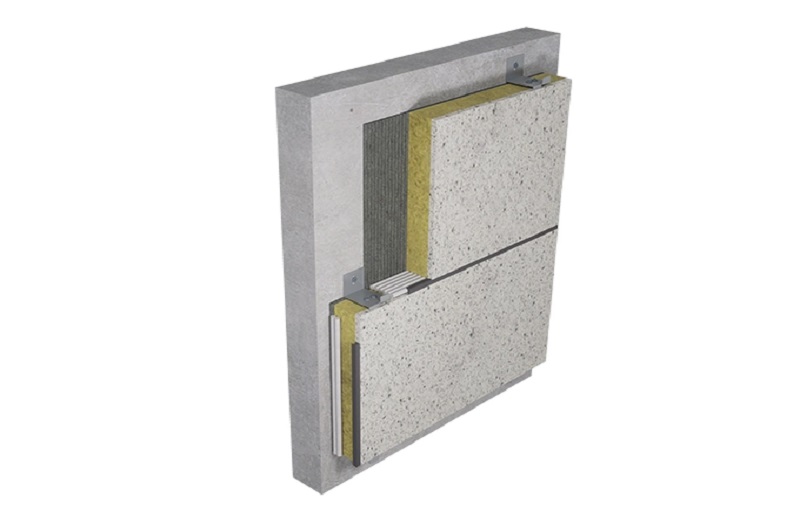

Cleanroom panels are sandwich-type composite boards designed specifically for cleanroom projects. With high-quality color-coated steel sheets as the surface and rock wool, PU, or EPS as the core material, they combine structural strength, smooth aesthetics, and hygienic performance in one solution. Their flat, seamless surface helps reduce dust accumulation and supports easy cleaning, ensuring compliance with GMP and ISO cleanroom standards.

Superior Cleanliness – Smooth, anti-static, and antibacterial surfaces effectively prevent particle buildup.

Excellent Insulation – Rock wool and PU cores deliver high fire resistance and thermal efficiency.

Customizable Solutions – Panels can be designed with different thicknesses, finishes, and installation methods for specific cleanroom grades.

Quick Installation – Prefabricated modular design allows for fast assembly, reducing project timelines.

Cleanroom panels are widely applied in:

Pharmaceutical factories (GMP workshops, sterile production areas)

Electronics manufacturing (semiconductor plants, precision instrument rooms)

Food processing (hygienic packaging, cold storage)

Hospitals and labs (ICU wards, testing centers, research facilities)

As an industry leader with over 30 years of expertise, HEADSTREM Holding Group provides comprehensive cleanroom panel solutions – from material design and customized production to logistics and on-site technical support. With reliable quality and global service capability, HEADSTREM helps clients build clean, safe, and sustainable environments worldwide.

English

English  Español

Español  العربية

العربية