Search

In today’s digital era, screens are everywhere. From automotive displays and virtual reality to smartphones and wearable devices, display technologies are constantly reshaping our visual experience. As demand for high-performance displays continues to surge, the construction of world-class display manufacturing bases has become a shared goal of leading global tech enterprises.

BOE Technology Group, a global leader in the semiconductor display industry, is building the world’s most advanced LCD manufacturing base with its 6th-generation new semiconductor display device production line project. HEADSTREAM is proud to contribute to this landmark project by providing a critical building envelope solution — the QuadFacade® Curtain Wall System.

1. Fire Safety – Protecting Critical Facilities

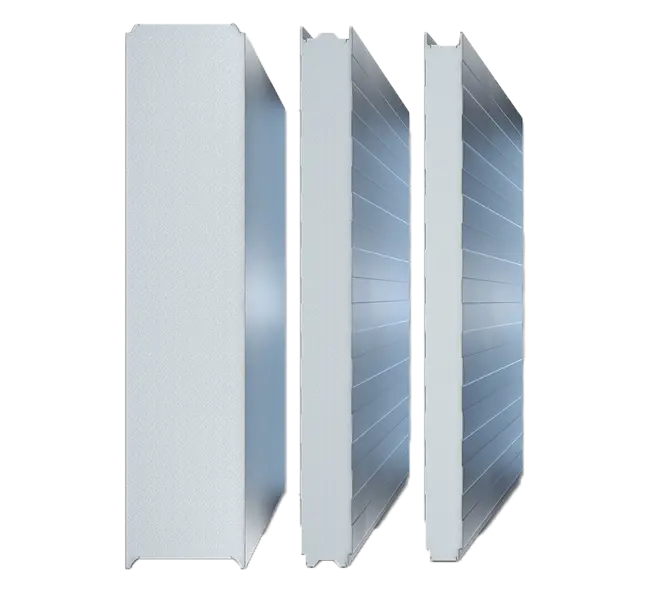

In semiconductor manufacturing, fire safety is paramount. HEADSTREAM has developed a new system — the HXY-FD-W-SHEB pure rock wool metal curtain wall panel — based on its four-edge interlocking sandwich panel system. This product features a non-combustible rock wool core, offering excellent fire resistance and physical isolation, effectively preventing the spread of fire within high-end industrial buildings.

2. Thermal Insulation – Ensuring a Stable Environment

In addition to fire protection, the rock wool core provides outstanding thermal insulation. The precisely fitted joints and heat-bridge control design help maintain a stable indoor temperature, creating ideal conditions for the precise manufacturing of display panels.

3. Airtightness – Guaranteeing a Cleanroom Environment

To meet the stringent cleanliness standards of display panel production, the QuadFacade® system uses an airtight-guided design. During installation, the team employed glue-overflow techniques to further enhance the external wall’s sealing performance, effectively preventing dust and pollutants from entering the workshop. It also reduces noise transmission, contributing to the development of green, efficient industrial buildings.

4. Prefabricated Installation – Boosting Efficiency

As a typical insulated building panel, the system’s modular design and prefabricated construction significantly reduced installation complexity while improving efficiency and quality. As a result, the main workshop and power center construction were completed 45 and 37 days ahead of schedule, respectively — helping the project reach its impressive goal of topping out within the same year and lighting up production the following year.

5. Eco-Friendly & Durable – Supporting Sustainability

QuadFacade® curtain wall panels align with green building principles. Their use of sustainable materials and durable coatings ensures long-term operational stability while reducing maintenance costs. HEADSTREAM's commitment to sustainability is reflected in every detail.

The successful mass production of BOE’s 6th-generation display project marks another major breakthrough in China's high-end display industry. HEADSTREAM is honored to play a part in this achievement.

Looking forward, HEADSTREAM will continue to focus on building construction composite panels innovation, enhancing its product lines and solutions to support more technology enterprises in reaching new heights. Together, we can drive the growth and evolution of the global tech industry.

English

English  Español

Español  العربية

العربية