Search

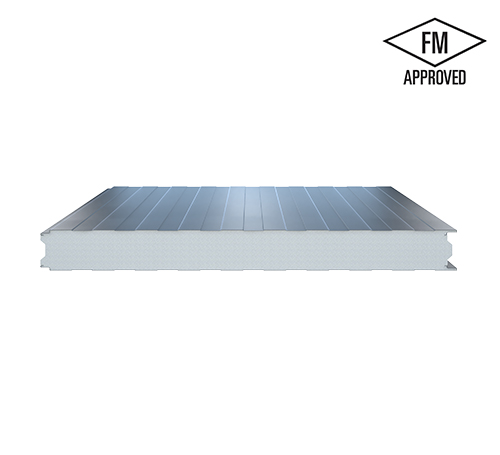

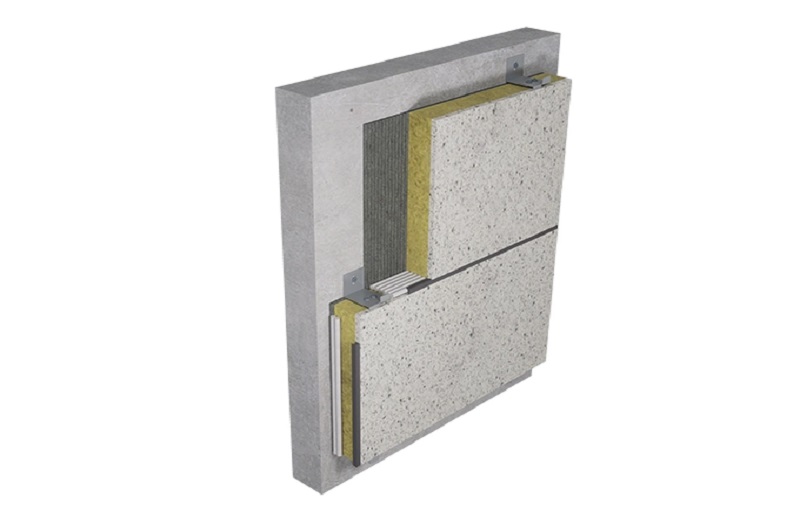

EPS (Expanded Polystyrene) wall panels are prefabricated building components featuring a lightweight EPS foam core sandwiched between durable facings. Typical facings include:

Cement board

Fiber-reinforced cement

Metal sheets

Gypsum board

The EPS core provides thermal insulation, while the facings deliver structural support and surface protection. These EPS sandwich panels are suitable for both load-bearing and non-load-bearing applications, depending on design and facing materials.

1. Thermal Insulation

Thermal conductivity (λ): 0.032–0.038 W/m·K

Typical thickness: 50–150mm

Example: 100mm panel ≈ R-3.0 to R-3.1 (m²·K/W)

Helps achieve energy-efficient building envelopes compliant with codes such as ASHRAE 90.1 and IECC

2. Mechanical Strength

EPS density: 15–30 kg/m³

Compressive strength: 80–150 kPa (core only)

Facings enhance bending and impact resistance

3. Fire Performance

EPS is combustible but can be enhanced with fire-retardant additives

Fire-resistant facings improve safety ratings

Compliant with ASTM E84, EN 13501-1, or local regulations

4. Moisture & Vapor Resistance

Low water absorption (<1%) reduces risk of mold and degradation

Proper sealing and vapor barriers are recommended for exterior or humid applications

ASTM C578: EPS thermal insulation properties

EN 13163: European standard for EPS insulation

ASTM E84: Surface burning characteristics

ISO 9001: Manufacturing quality management

Local and international building codes for safety and compliance

Structural Design

Panels must account for wind, seismic loads, and live loads

Select facing materials and core thickness based on project requirements

Best Practices

Ensure plumb, square substructures

Use compatible fasteners and adhesives

Seal joints with fire-resistant materials

Include thermal breaks and expansion joints

Safety

Use PPE during cutting and installation

Ensure proper ventilation to minimize dust

Follow waste management protocols for EPS scraps

Can reduce heating/cooling energy consumption by up to 35%

100mm EPS core panels with cement facings can withstand compressive loads >200 kPa

Fire-retardant systems achieve Class B or better in flame spread and smoke tests

EPS wall panels are lightweight, thermally efficient, and versatile, suitable for residential, commercial, and industrial projects. For optimal performance, consult construction engineers and manufacturers to ensure panels meet project-specific requirements, safety standards, and local regulations.

English

English  Español

Español  العربية

العربية