Search

In modern building envelope systems, metal-faced sandwich panels have become a mainstream choice for industrial facilities and public buildings. Thanks to their combined structural performance, customizable surface finishes, and modular installation efficiency, these panels offer superior functionality and aesthetics.

The quality of metal-faced sandwich panels hinges on three technical foundations:

A long-lasting protective outer layer

A stable and efficient core material structure

Precision in the entire manufacturing and installation process

Without strict process control during production, composite panels are prone to defects such as surface cracking, delamination, and bulging, which compromise both structural integrity and energy efficiency.

Poor Processing: Substandard adhesive bonding can cause delamination and bulging, accelerating material aging. Rough cutting or bending leaves sharp edges and exposes core material, allowing moisture to penetrate.

Surface Defects: Inferior panels often use low-strength substrates, leading to cracking or deformation. Uneven coating thickness results in color inconsistencies, chalking, and fading under sunlight—making the surface look aged within just a year or two.

Core Material Hazards: Inadequate control of closed-cell rate and core density uniformity leads to reduced thermal performance. Absorption of moisture causes internal corrosion and, in winter, condensation may collapse the insulation layer entirely.

Surface Material: HEADSTREAM partners with global steel suppliers to ensure high-strength substrates with smooth, crack-free surfaces. Custom finishes like stone or wood grain are available, offering outstanding weather resistance and long-lasting color stability.

Core Material: In collaboration with Wanhua Chemical, the building panel manufacturer has developed a high-performance PIR core system with low thermal conductivity and excellent fire resistance. The high-pressure continuous foaming process ensures over 97% closed-cell rate and uniform internal structure. Directional rock wool fibers provide superior compressive strength and fire rating.

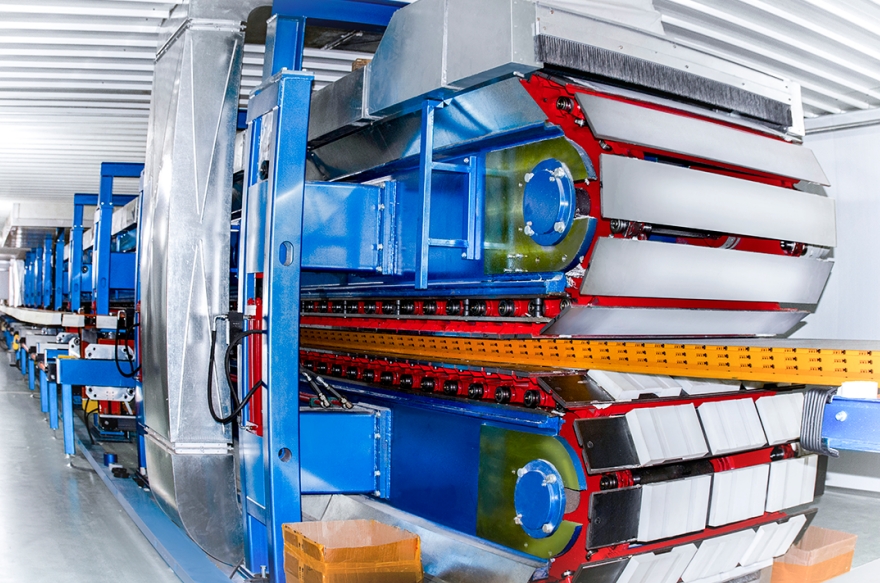

Smart Manufacturing System: HEADSTREAM employs fully imported advanced production equipment. Ultra-long dual-belt laminators and automatic curing systems guarantee panel consistency. Automated cutting systems deliver millimeter-level precision, while servo-controlled CNC folding machines eliminate manual errors in forming complex shapes.

Refined Finishing: Protective film application during profiling protects the paint surface from damage throughout production, transport, and installation. Corona treatment enhances coating adhesion. Accurate glue control and pressure regulation ensure perfect bonding between core and skin, preventing delamination and bulging. Peel strength reaches industry-leading levels.

Strict Quality Control: HEADSTREAM operates an in-house testing center that simulates extreme climates—conducting freeze-thaw cycles, salt spray corrosion, and fire resistance tests to ensure product reliability throughout its lifecycle. Here Click for High-quality Sandwich Panels for Sale

At HEADSTREAM, top-tier service is an essential component of product excellence. Thanks to outstanding product performance, industry-leading delivery speeds, and full-cycle support, HEADSTREAM has earned the trust and praise of top-tier clients and major construction projects.

Clients recognize HEADSTREAM for its "consistent high standards" and "comprehensive solution capability"—reflected in completed projects and countless heartfelt thank-you letters. These endorsements underscore our philosophy: to ensure clients purchase with confidence and use with peace of mind.

By continuously innovating in materials, refining manufacturing techniques, and advancing intelligent production, HEADSTREAM leads the transformation of metal envelope systems from experience-driven to standardized smart manufacturing—delivering precise, efficient solutions for energy-efficient renovations, industrial facilities, urban redevelopment, and public buildings.

English

English  Español

Español  العربية

العربية