Search

In industries with extremely high air cleanliness requirements such as pharmaceuticals, electronics, and food processing, the construction of clean rooms is critical. As the core material of clean room enclosure structures, clean room panels directly impact the overall space's airtightness, stability, and service life. HEADSTREAM, as a professional supplier in the clean room panel industry, is dedicated to providing high-performance, customizable panel solutions for various clean projects, helping clients efficiently build production environments that meet diverse cleanroom classification standards.

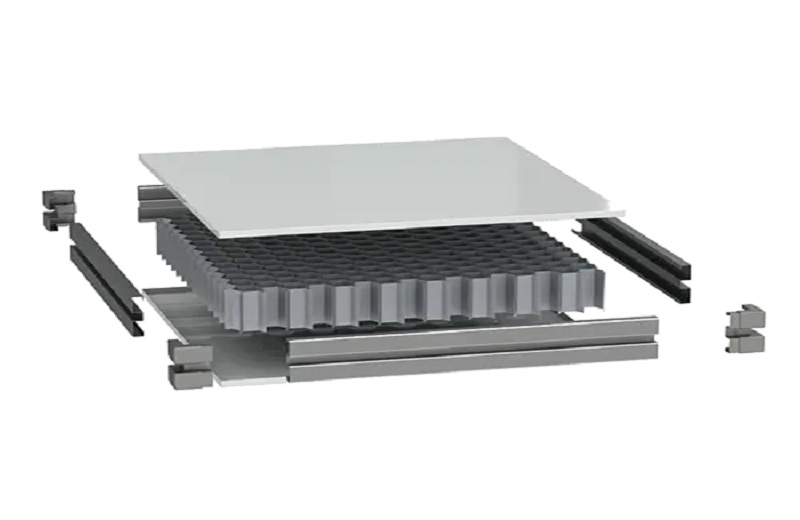

Manual clean room panels feature a four-sided embedded arched galvanized steel keel design, with wall connections achieved through central aluminum profiles, and ceilings equipped with concealed hanging beam structures to ensure a clean and aesthetic overall appearance. This product type offers stable structure, excellent compressive strength, and flatness, suitable for walls and ceilings in various clean areas. As a modular sandwich panel with internal frame support, manual clean room panels are easy to install and highly adaptable. HEADSTREAM's manual clean room panels support various surface materials and core options such as rock wool, silica rock, and aluminum honeycomb, customizable to different cleanliness levels and functional requirements. They are widely used in GMP pharmaceutical plants, electronics workshops, and food cleanrooms with high standards.

For standardized and large-batch projects, HEADSTREAM offers machine-made clean room panels featuring male-female interlocking connection systems and "rainbow keel" edge sealing technology. Ceilings are installed with exposed hanging beams, resulting in a compact structure and high construction efficiency. Machine-made panels include standard versions and can be customized with anti-static and antibacterial functionalities, especially suitable for electronic cleanrooms and high-traffic areas. Surface treatments provided by HEADSTREAM include various coatings such as Z, AZ, and AZM, along with PE, PVDF, HDP, and SMP finishes, meeting diverse corrosion resistance and oxidation prevention requirements to ensure long-term durability and aesthetics.

| Core Feature | Description |

| Airtightness & Insulation | Exceptional airtightness and thermal insulation ensure long-term stable operation of clean rooms. |

| Functional Extensions | Diverse options including antibacterial, anti-static, moisture-proof, and fire-resistant functionalities. |

| Specification & Finish | Wide range of sizes and customizable surface finishes to suit various engineering design requirements. |

| Professional Support | Experienced team providing full-process service from product selection to installation. |

Whether it is a pharmaceutical production environment demanding high cleanliness or an electronics manufacturing space requiring special anti-static properties, HEADSTREAM delivers professional and efficient clean room panel solutions. Choosing HEADSTREAM means building clean spaces with greater confidence and higher efficiency.

English

English  Español

Español  العربية

العربية