Search

Manual clean room panels, as a type of high-performance sandwich panel clean room system, stand out in various high-cleanliness construction projects due to their modular structure, excellent sealing performance, and customizable material combinations. Below are representative application cases across three major industries, highlighting their value and advantages in different settings.

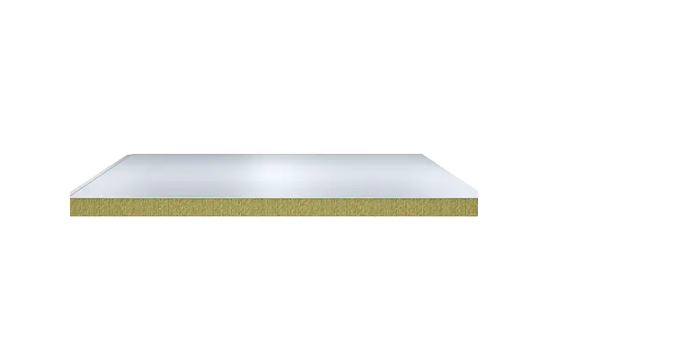

Manual clean room panels are factory-manufactured modular wall or ceiling systems used in cleanroom environments. They are typically made from sandwich structures with various core materials (e.g., rock wool, paper honeycomb, PU) and surface coatings (e.g., galvanized steel, aluminum-magnesium-manganese). Known for their precision, durability, and adaptability, they support internal wiring and piping layouts while ensuring compliance with strict cleanliness standards.

GMP (Good Manufacturing Practice) certification imposes stringent cleanliness level requirements on pharmaceutical facilities, demanding environments that are dust-proof, contamination-resistant, and easy to clean. Manual clean room panels are the ideal material for walls and ceilings in such areas due to their high strength, strong sealing ability, and smooth surfaces.

Optional antibacterial coatings and dust-free installation methods help reduce microbial adhesion and particle contamination, ensuring consistent compliance with cleanliness levels from Grade A to D. Their internal structure supports integrated wiring and concealed pipeline layouts, facilitating equipment integration and maintenance. As one of professional clean room panels suppliers, HEADSTREAM has widely applied its manual clean room panels in core areas such as API workshops, aseptic preparation rooms, and biopharmaceutical zones.

Medical device workshops require extremely precise environmental control. Tiny particles, temperature/humidity fluctuations, and static interference can all impact production quality. Manual clean room panels offer exceptional airtightness and can be paired with antistatic and antimicrobial coating options, effectively reducing the risk of static accumulation and improving environmental stability.

In addition, their outstanding corrosion resistance and chemical tolerance make them ideal for frequently disinfected environments. The modular installation method allows for flexible room configurations to meet evolving equipment layouts and process requirements. For medical enterprises seeking long-term reliability and ease of maintenance, high-quality sandwich panel clean room solutions are critical to ensuring production efficiency and safety.

In food processing environments, air cleanliness and structure sealing are directly linked to product hygiene and safety. Manual clean room panels feature mold-resistant, moisture-proof, and corrosion-resistant properties to withstand humid, greasy, and frequently cleaned environments. Their smooth, seamless joint design prevents dust accumulation.

In dairy, bakery, condiment, and beverage production areas, using manual panels for walls, ceilings, and partition zones effectively prevents cross-contamination and elevates overall hygiene standards. Moreover, panels can be tailored with anti-corrosion coatings and food-grade interiors to meet specific processing requirements.

| Industry | Environmental Requirements | Manual Panel Features | Example Applications |

|---|---|---|---|

| Pharmaceutical | GMP-grade cleanliness, microbial control, ease of cleaning | Antibacterial coatings, smooth surface, airtight structure | API plants, sterile rooms, biotech clean zones |

| Medical Devices | Particle control, temperature/humidity stability, static resistance | Antistatic options, high chemical resistance, modular configuration | Precision assembly lines, surgical device manufacturing |

| Food Processing | Hygiene, humidity/mold resistance, corrosion resistance | Seamless panels, food-safe coatings, moisture-proof construction | Dairy, baked goods, condiment, beverage clean zones |

HEADSTREAM, as one of experienced clean room panels suppliers, offers not only top-quality sandwich panel clean room solutions but also ensures high-standard delivery and reliable performance across cleanroom construction projects.

English

English  Español

Español  العربية

العربية