Search

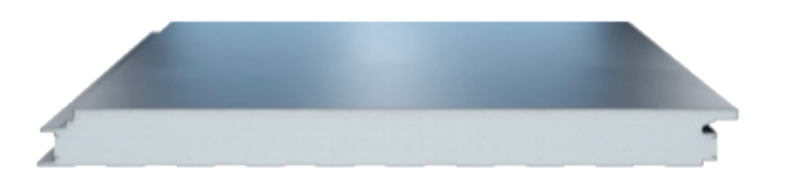

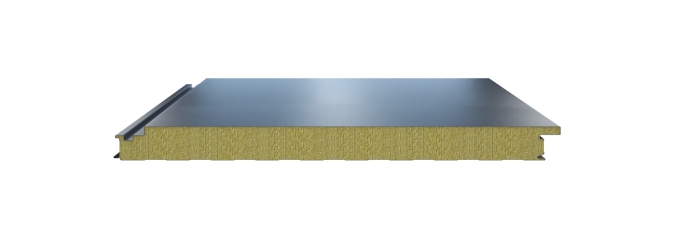

Sandwich panels are high-performance composite building materials made by bonding metal facings to insulating cores. The choice of core material plays a decisive role in the panel’s thermal performance, fire resistance, structural strength, and sound insulation capabilities.

Here are the common types of core materials used in sandwich panels:

Polyurethane (PU) is widely used for its excellent thermal insulation and moisture resistance. It is ideal for cold storage facilities, roofing systems, and building envelopes.

Polyisocyanurate (PIR) builds upon PU’s strengths while offering enhanced fire resistance and better thermal stability, making it suitable for high-safety industrial projects.

Rock wool is a non-combustible mineral fiber core that provides outstanding fireproof and acoustic performance. It’s extensively applied in industrial plants, fire partitions, and power stations.

Glass wool is lightweight and offers both insulation and basic fire resistance. It’s commonly used in public buildings and light industrial structures.

Expanded Polystyrene (EPS) is a cost-effective and lightweight option with moderate insulation performance, often chosen for temporary buildings and basic warehousing.

Extruded Polystyrene (XPS) delivers higher compressive strength and better moisture resistance, making it a good fit for roofing, floor insulation, and cold chain projects.

Magnesium Oxide Board (MgO) is an inorganic, fireproof core material with A1-grade fire resistance. It is moisture-resistant, eco-friendly, and dimensionally stable, widely used in cleanrooms, medical facilities, and modular buildings.

For applications where weight and structure optimization are crucial, honeycomb cores—such as paper or aluminum honeycomb—provide lightweight strength and structural stability. These are often used in modular construction, decorative panels, and transport applications.

Our company offers a wide range of sandwich panels with different core materials, tailored to meet specific needs across various industries. Contact us for customized recommendations and technical support.

English

English  Español

Español  العربية

العربية