Search

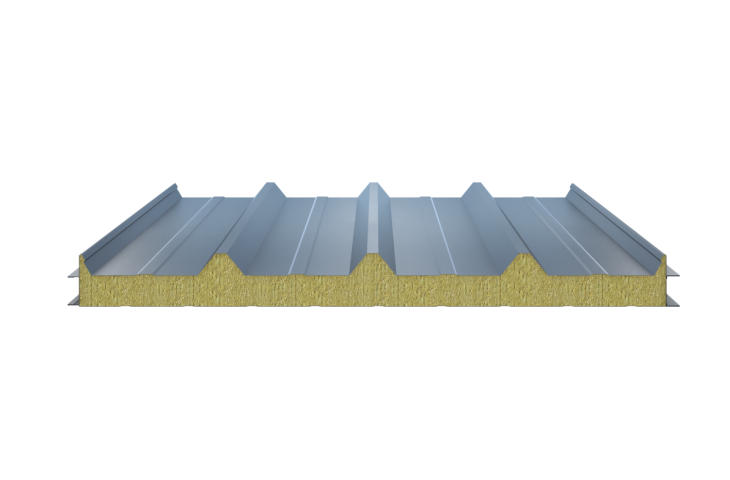

HEADSTREAM Rock Wool Sandwich Panels are manufactured with premium rock wool as the core material, using advanced production technology to ensure excellent performance in fire resistance, thermal insulation, acoustic control, and durability. They are widely applied in industrial facilities, cold storage, cleanrooms, and buildings requiring high levels of fire protection.

1. Outstanding Fire Resistance

Rock wool core can withstand temperatures exceeding 1000°C.

Certified by authoritative fire-resistance tests, meeting A1 non-combustible standards in compliance with international regulations.

2. Superior Thermal Insulation

Based on a rock wool thermal conductivity of λ=0.043 W/㎡·K.

Effectively reduces energy consumption, making it ideal for cold rooms, refrigerated warehouses, and temperature-controlled facilities.

3. Excellent Acoustic Performance

Sound insulation: Rock wool sandwich panels significantly reduce noise transmission. When using a core density of 120kg/m³, sound reduction levels reach RW = 29–30 dB, tested according to ISO 717/82 and UNI 8270/7 standards.

Sound absorption: Provides outstanding absorption across a wide frequency range, improving indoor acoustic comfort.

4. Enhanced Durability with PU Sealed Edges

PU edge sealing technology prevents moisture absorption, improving water resistance and extending product lifespan.

Panels feature a smooth, flat surface with tight joints and reliable strength, ensuring both functionality and aesthetics.

Thickness options: 50mm, 75mm, 100mm, 125mm, 150mm

Density options: 60kg, 80kg, 100kg, 120kg, 140kg

Length & Width: Customized according to client requirements

Standard Rock Wool Sandwich Panels

PU Edge-Sealed Rock Wool Sandwich Panels

Rock Wool Cleanroom Panels

Applications include:

Cleanrooms for pharmaceuticals, electronics, biotechnology

Food and beverage processing plants

Cold storage and preservation facilities

Modular houses, container buildings, and partitions

Industrial plants requiring enhanced fire protection

Factory-Produced Panels (Recommended):

Manufactured with fully automated production lines for stable quality, excellent air-tightness, and water resistance.

On-Site Assembled Panels:

Constructed by layering steel sheets and rock wool directly at the site. While cost-effective, they typically provide lower sealing performance and reduced service life compared to factory-made panels.

With over 30 years of experience in steel structures and composite panels, HEADSTREAM provides building materials that combine safety, energy efficiency, and long-term reliability. Our advanced production facilities and international certifications guarantee products that meet the highest standards.

English

English  Español

Español  العربية

العربية