Search

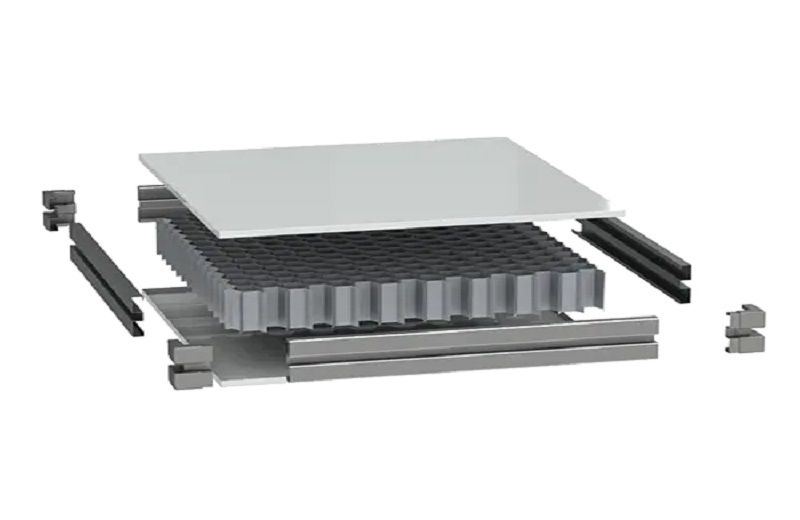

A PUF Wall Panel (Polyurethane Foam Wall Panel) is a modern sandwich panel system known for its excellent insulation, fire resistance, and quick installation. These panels are made by injecting rigid polyurethane foam between two metal or non-metal facings, forming a strong and durable composite structure.

PUF wall panels are widely used in industrial buildings, warehouses, cold rooms, cleanrooms, and commercial facilities, helping reduce energy consumption while maintaining temperature stability.

The performance of a PUF wall panel comes from its smart material combination:

1. Insulation Core – Polyurethane Foam (PUF)

Polyurethane foam is the heart of every PUF insulated wall panel.

Thermal Efficiency: PUF provides superior insulation with low thermal conductivity, keeping interiors warm in winter and cool in summer.

Lightweight but Strong: Easy to handle and install, reducing labor costs.

Moisture and Fire Resistance: PUF’s closed-cell structure prevents water absorption and supports fire safety requirements.

2. Outer Facings

The polyurethane core is sandwiched between two protective layers that enhance durability and appearance. Common facing materials include:

Galvanized or Pre-painted Steel: Offers strength, weather resistance, and long lifespan.

Aluminum Sheet: Lightweight and corrosion-resistant, suitable for coastal or humid areas.

3. Adhesive Layer

A high-performance PU or epoxy adhesive bonds the core and facings together. This ensures long-lasting stability, impact resistance, and structural integrity.

4. Protective Coating

To improve aesthetics and extend service life, outer surfaces are often coated with PVDF, polyester, or powder coatings, providing excellent UV and corrosion resistance.

Superior Insulation Efficiency – Reduces heating and cooling energy costs by up to 40%.

Fire Resistance – Can meet international fire safety standards when used with metal facings.

Quick and Easy Installation – Prefabricated panels reduce onsite labor and construction time.

Durability and Weather Resistance – Withstands harsh weather, corrosion, and aging.

Eco-friendly Material – PUF panels are energy-efficient and recyclable.

Whether you’re constructing a cold storage room, factory wall, or cleanroom enclosure, a PUF sandwich panel delivers reliable thermal and structural performance for years.

PUF wall panels are suitable for a wide range of industries and facilities, such as:

Cold Storage & Freezer Rooms

Food Processing Plants

Pharmaceutical Cleanrooms

Industrial Warehouses

Commercial Buildings & Offices

Residential and Modular Houses

Their versatility and cost-effectiveness make them one of the most popular choices in modern prefabricated construction.

At HEADSTREAM, we specialize in manufacturing high-performance PUF wall panels with advanced production lines and strict quality control. Our panels are customizable in thickness, color, and surface type to meet your specific project needs.

If you’re looking for an insulated wall panel manufacturer that offers reliability, durability, and energy savings — HEADSTREAM is your trusted building panel manufacturer for every building solution.

English

English  Español

Español  العربية

العربية