Search

In pharmaceuticals and food processing, hygiene and contamination control are critical. Even minor impurities can compromise product quality, safety, and brand reputation. HEADSTREAM clean room sandwich panel create controlled environments that meet strict regulatory standards for cleanliness, air quality, and temperature stability, ensuring safe and efficient operations.

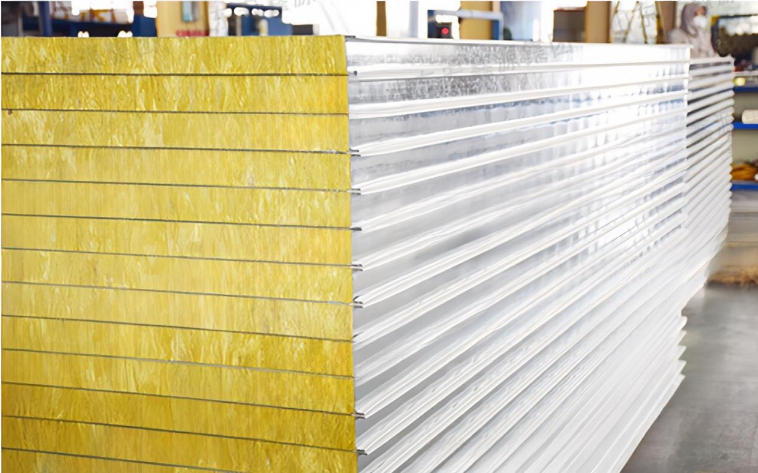

HEADSTREAM clean room panels, made from PUF, PIR, or EPS, feature airtight sealing and smooth, non-porous surfaces that prevent microbial growth and dust accumulation. Easy to clean and resistant to bacteria, these panels maintain ultra-clean environments essential for compliance with hygiene regulations.

Pharmaceutical and food facilities must adhere to standards like WHO-GMP, FDA, ISO 14644, and HACCP. HEADSTREAM panels support controlled temperature, humidity, airflow, and seamless surfaces compatible with HEPA filtration, enabling companies to pass audits and maintain global compliance.

Fluctuations in temperature or humidity can degrade sensitive products. HEADSTREAM panels provide superior insulation to maintain stable conditions while supporting advanced air filtration systems. This ensures sterile environments for medicine formulation, dairy packaging, and other sensitive production processes.

Our clean room sandwich panels resist corrosion, chemicals, and impact, essential for facilities requiring frequent cleaning with disinfectants. Modular construction allows easy replacement or reconfiguration without disrupting operations, while routine cleaning keeps the system performing efficiently for years.

Modular and prefabricated, HEADSTREAM panels can be installed, expanded, or relocated quickly, minimizing downtime. This flexibility allows pharmaceutical and food plants to adapt to production changes or new product lines without costly remodeling.

PUF and PIR panels provide excellent thermal insulation, reducing the load on HVAC systems. Stable internal conditions improve energy efficiency, lower operational costs, and contribute to sustainable, eco-friendly operations.

Smooth, glossy surfaces give production areas a high-tech, hygienic look. A clean, organized environment reflects a company’s commitment to quality, safety, and excellence, important for clients, auditors, and regulatory inspections.

HEADSTREAM clean room panels are ideal for pharmaceutical formulation rooms, packaging units, food processing areas, laboratories, cold storage, and controlled warehouses. Their versatility supports multiple production stages requiring strict cleanliness and control.

Made from eco-friendly, recyclable materials, our panels support green operations. Combined with energy efficiency and low maintenance, they help companies meet global environmental standards.

For pharmaceutical and food industries, HEADSTREAM Clean Room Panel Systems are essential for product integrity, safety, and regulatory compliance. They create sterile, controlled environments, improve energy efficiency, and simplify maintenance, ensuring long-term operational reliability and enhancing brand trust.

English

English  Español

Español  العربية

العربية